User Research

User research provides discovery, insight, and guidance to the creative process. We verify user requirements, test assumptions and proposed concepts. We optimize the design for usability. We use observation and professional insight for timely, efficient and cost effective research.

Initial Analysis: We evaluate the client’s assumptions, proposed design solutions, and target users.

Formative Testing: We may interview users and simulate use. This confirms assumptions, discovers user insights and misconceptions. The goal is periodic guidance of the development process.

Task Analysis: We create a list of sequential steps, decision points, control actions and feedback loops. This is used to guide risk analysis, formative testing, and use simulation. This creates a metric for comparing alternative concepts.

Ergonomics: We define a user population, their physical size, strength and cognitive capabilities. This guides evaluation of comfort and safety. This is an early step in our design process.

Product Use Simulations: We develop simulated use scenarios. These scenarios consider the product life cycle. This includes first time setup and training, ordinary use, and maintenance. The goal is to define critical objectives for each area of concern.

Summative Testing: Our formative testing creates the foundation for successful summative test results. We refer formal summative testing to our expert consultants or our clients.

Industrial Design

Team: Our designs show our team’s industrial design capability. We create iconic designs, with optimized ergonomics. Users see and feel the quality of our designs. Design awards recognize our professional achievements. The market rewards our clients for great designs.

Design Process: We consider management objectives, user needs, market trends and technology. We design concurrently with engineering. We push past preconceived limits to achieve exceptional results.

Start: We clarify C-level design goals and vision. We define how design will support the company's strategy.

Function First: We create functional concepts that optimize product size, human factors, and solve system engineering problems. User research guides human factor considerations. Our engineering team concurrently proves feasibility through analysis and testing. We create a foundation design concept that is feasible, well proportioned, and solves major engineering problems.

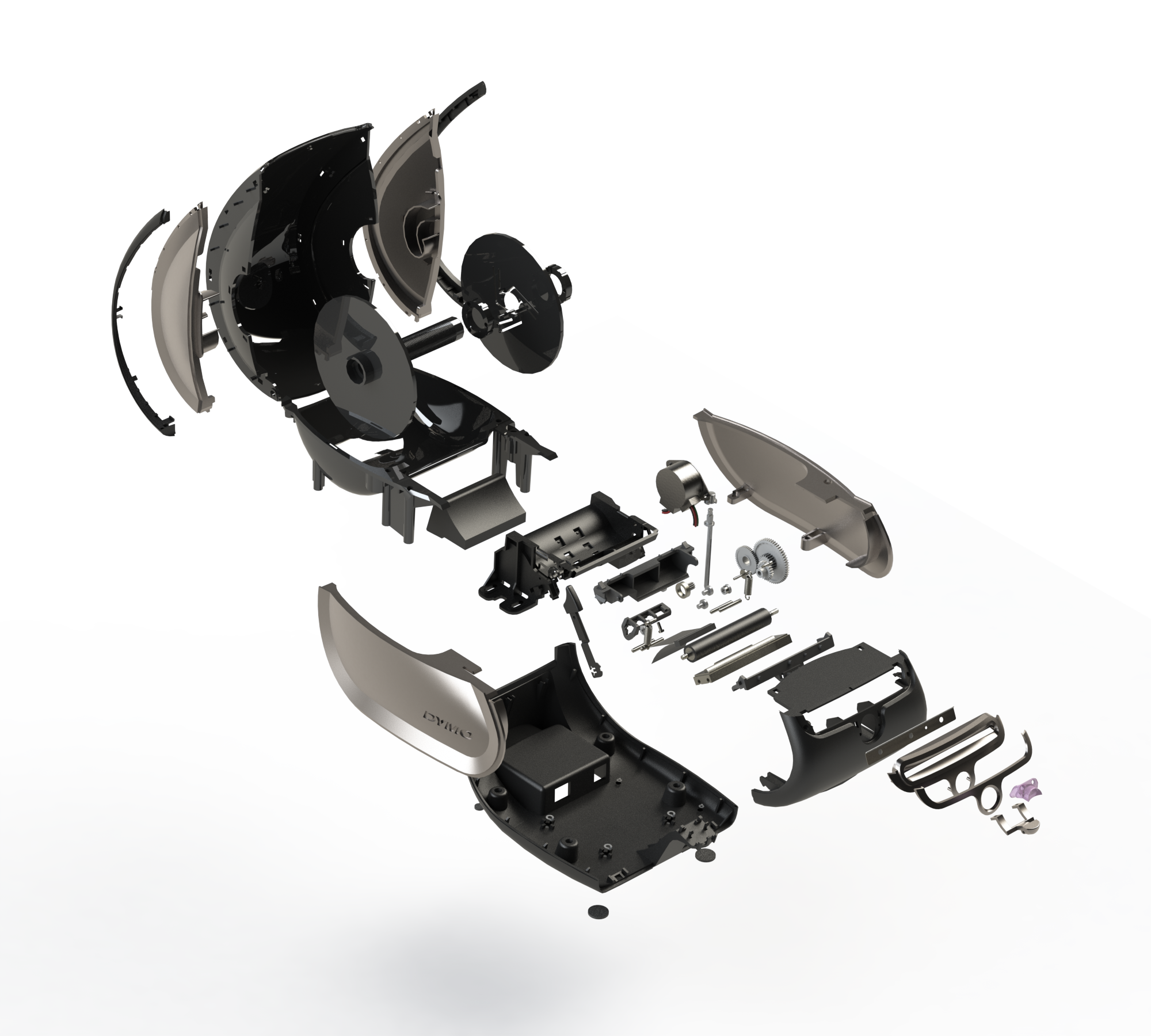

Design Concepts: We create design concepts that inspire our visionary clients. We go beyond preconceived boundaries. Our concepts express a brand message, the creative use of materials, and aesthetic forms. Concepts are developed concurrently with engineering, usability testing, and design for manufacturing. The result is an inspired design concept that is technically feasible with a clear path to manufacturing.

Final Design: We transition from concept development to a production design. Our industrial design team defines the product’s exact final form, details, finishes and graphics. Concurrently, our engineering team develops the production design for manufacturing.

Mechanical Engineering

Team: We have an experienced mechanical engineering team. They transform our industrial design concepts into beautiful, production-ready designs. They seek challenges, find practical solutions to difficult problems, and follow through to production.

Start: Our engineering and industrial design teams work concurrently. They evaluate inputs from clients such as components, specifications, difficult technical problems and regulations. We team up with every client and align to unified goals.

Functional Design: We document and verify pre-defined components. We create requirements that guide component selection. As our industrial design team develops concepts, our engineering team solves internal engineering problems such thermal management and structural durability. We use analysis tools such as FEA and CFD simulation. We design, build and test proof of concept models. We evaluate and mitigate risks throughout every project.

Engineering and Design for Manufacturing: We utilize our extensive experience designing, documenting and releasing new product designs for manufacturing. We create product cost and performance objectives for parts, assemblies and tooling. We select materials and processes. Tolerances are carefully managed. We collaborate with exceptional vendors. Our goal is a seamless transition through tooling and production release. Millions of dollars in tooling and parts have been built to specifications we defined. We have a quality process that assures predictable outcomes.

Regulatory Integration: We routinely design products to meet various UL, CE, RoHS and FDA regulations. We support the client through testing, provide design documentation, resolve any issues, and help guide the process. (See Regulatory Compliance.)

Prototype

Shorten Development Time: A picture is worth a thousand words, a model is worth a thousand pictures. Our in-house 3D printing allows us to work out out the design of small areas to confirm function/fit/form, or print large assemblies on our large format printer.

Rapid Iteration Minimizes Risk, Improves Quality: Our designs evolve and improve as we refine each iteration. By the time we commit to tooling or a pilot build, we have already seen potential issues and resolved them.

Alpha Prototype: 1-3 units created for user feedback, trade show, or investor input. These are fully functional prototypes that look like a production unit, but may not be fabricated from production materials.

Beta Prototype: 3-20 Units created to test issues of assembly and serviceability. These are also fully functional prototypes that look like a production unit. Ideally, these are fabricated from the production materials.

Low Volume Manufacturing 1-500 Units

Quality: We maintain design and engineering intent through to manufacturing.

Evolve the Design: By doing a short production run, clients can incorporate user and investor feedback.

Save Time Getting to Pre-Production: Our intimate knowledge of the product allows us to quickly transition to the pilot build. We identify manufacturing sources and strategies, obtain vendor quotes with 3D geometry, create a bill of materials and 2d drawing package

Production: We manage the supply chain, order and manage inventory, perform incoming part inspection and manage vendor rework. We create work instructions and assemble all parts and modify as needed. We perform testing with load cell or other protocol to meet client specifications. We work with our vendors on the design of the boxes to ensure protection standards are met. We serialize, box and palletize shipments to client’s warehouse.

Regulatory Compliance

Regulatory Standards: All projects involve compliance with regulations set by recognized standards organizations. We routinely design products to meet various UL, CE, RoHS and FDA regulations. Passing tests and gaining approval is a team effort. The team is the client, Stream + Bleck PD, the supply chain and other consultants.

Our Role: We review the standards and identify each requirement in our design scope. We identify and reduce risks. We create levels of risk mitigation and contingencies for unpredictable outcomes. We evaluate materials and components before design integration. Periodic regulatory reviews with the client’s regulatory staff and third party consultants are normal steps. Early and thorough risk management leads to shorter approval times. For Class I and II medical devices we provide documentation compliant with ISO 13485.

Client’s Role: The client approves the product for sale. We support the client through testing, provide design documentation, resolve any issues, and help guide the process. If you are a start-up organization, your quality system may be developed concurrently with our efforts. For established firms, our proposal will define our regulatory compliance scope and mesh with your system.